- Report

- Photos

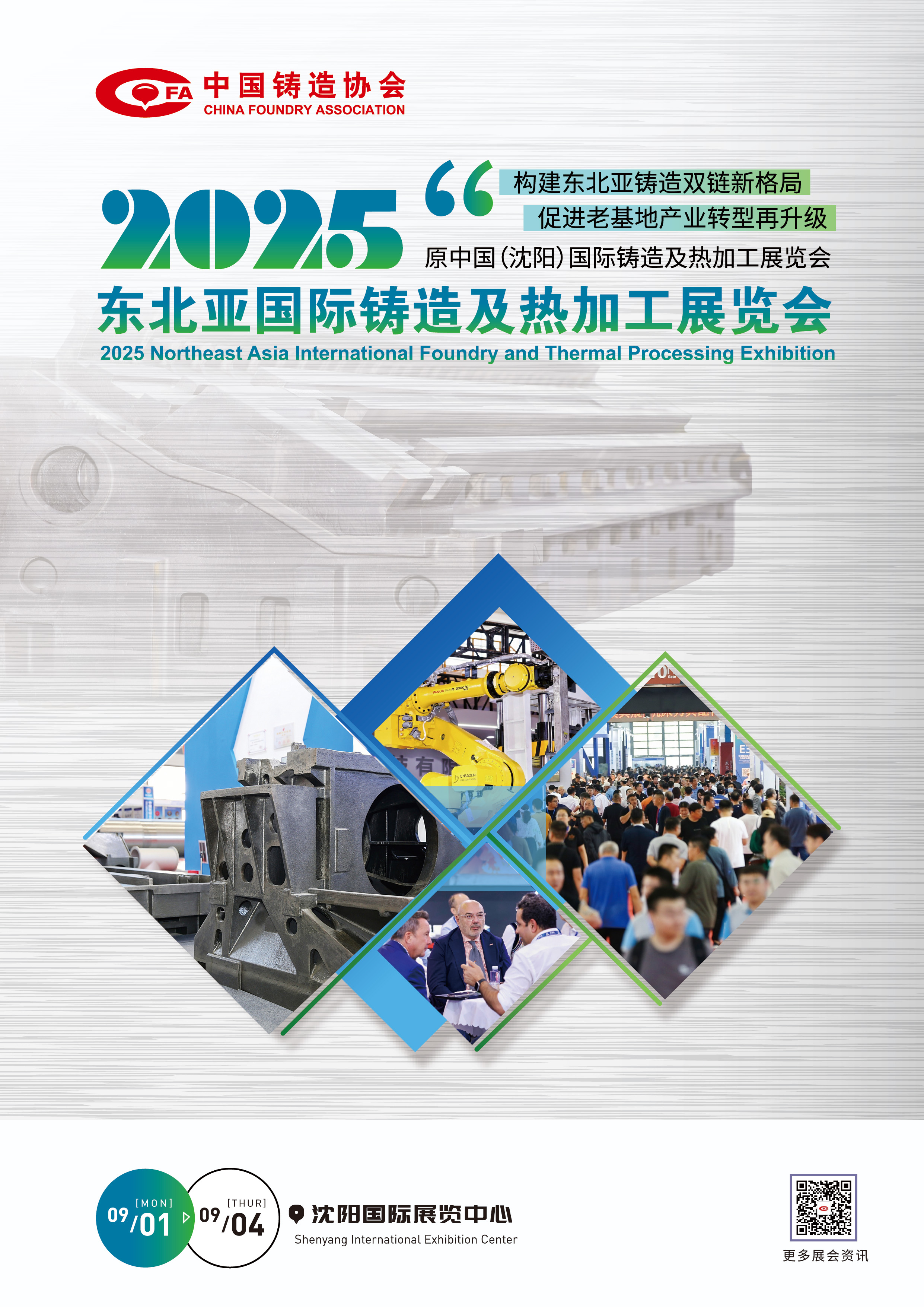

Old Base, New Insights: The 2025 Northeast Asia International Foundry Exhibition Concluded

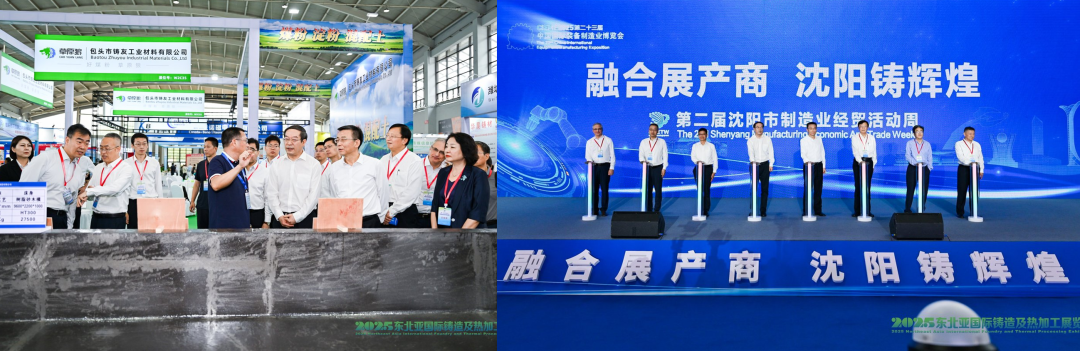

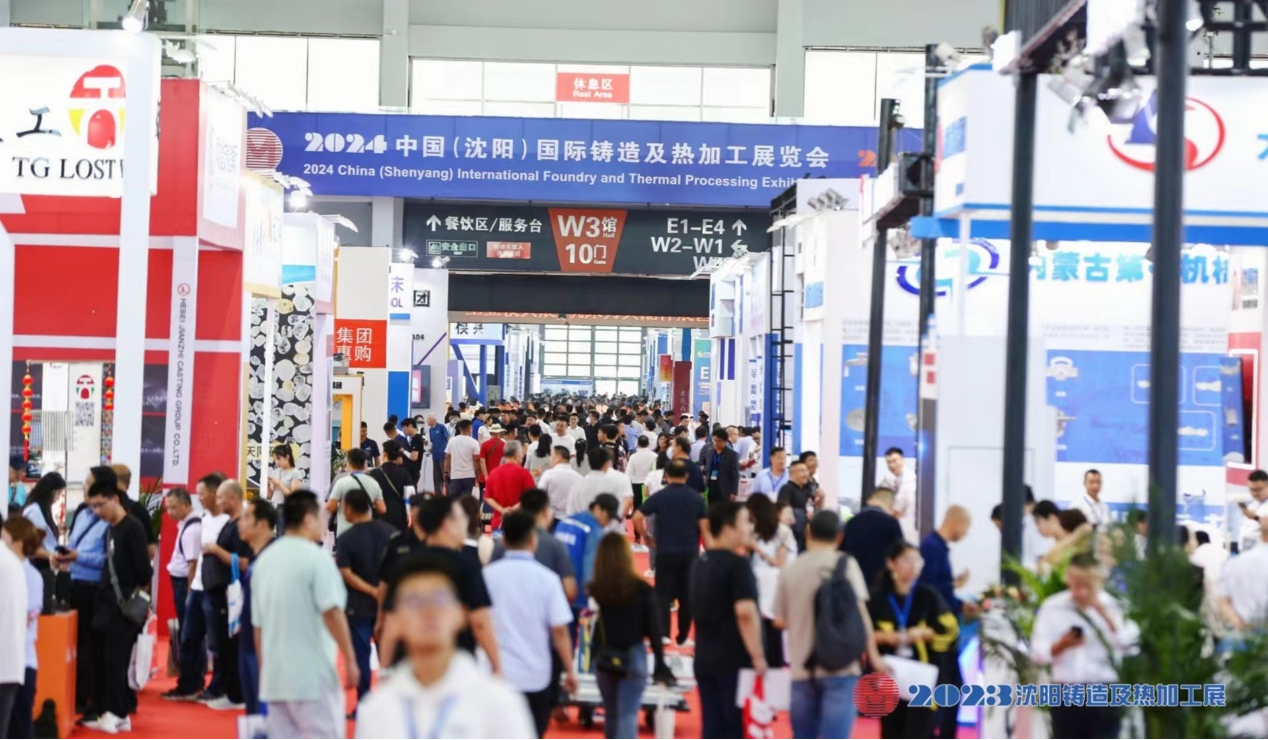

The 2025 Northeast Asia International Foundry Exhibition, lasted for four days from September 1-4, 2025, together with the 23rd China International Equipment Manufacturing Expo, came to a close at the Shenyang International Exhibition Center. Exhibitors and visitors received industry knowledge and resources, and were filled with warm expectations for win-win cooperation. With the mission of "building a new pattern of the foundry industry in Northeast Asia and promoting the transformation and upgrading of the old industrial base", they have been inspired with more driving forces for the industry development.

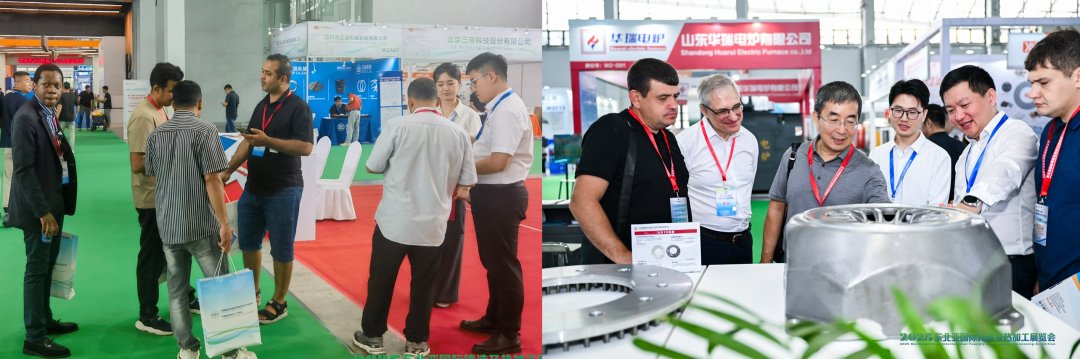

As an important part of the 23rd Manufacturing Expo, the 2025 Northeast Asia International Foundry Exhibition, with "foundry" at its core, gathered over 200 high-quality foundry enterprises from China, Japan, South Korea, Russia and other countries, achieving a wide layout covering the whole nation and radiating to Northeast Asia. During the four-day exhibition period, a batch of industry innovation achievements and technical solutions with international leading levels were presented, successfully building an information exchange ecosystem covering the entire industrial chain from raw material production to terminal sales. The exhibition precisely targeted the development needs of the entire manufacturing chain - focusing on key areas such as automotive manufacturing, high-end machine tool equipment, and rail transit equipment. It gathered the backbone forces of the industry through professional exhibition areas and planned the development direction of the industry through diverse activities, successfully building an international trade platform integrating exhibition and display, high-end dialogue, and resource connection for industry peers. It has achieved fruitful results in breaking regional barriers, promoting industrial cooperation, optimizing trade circulation, and assisting regional coordinated development, building a "bridge" for industrial upgrading in all-round revitalization and gathering strong synergy for deepening economic linkage and sharing development opportunities among Northeast Asian countries.

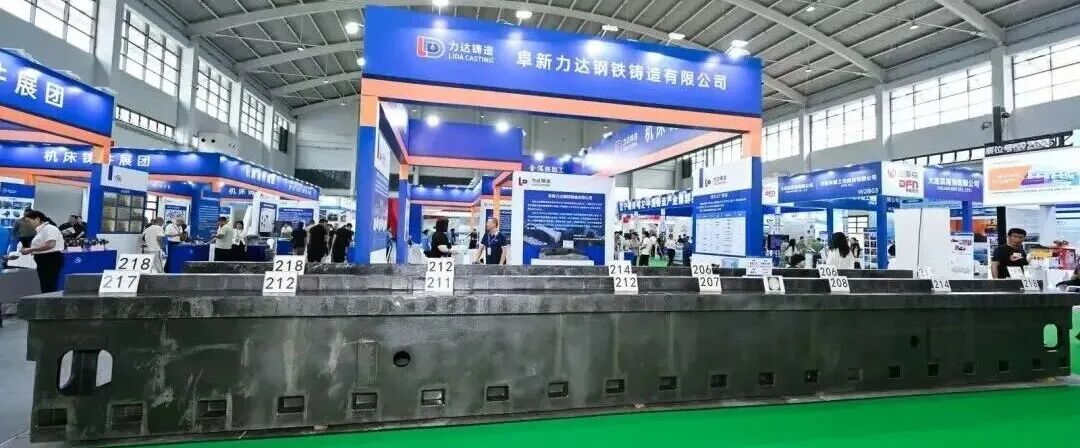

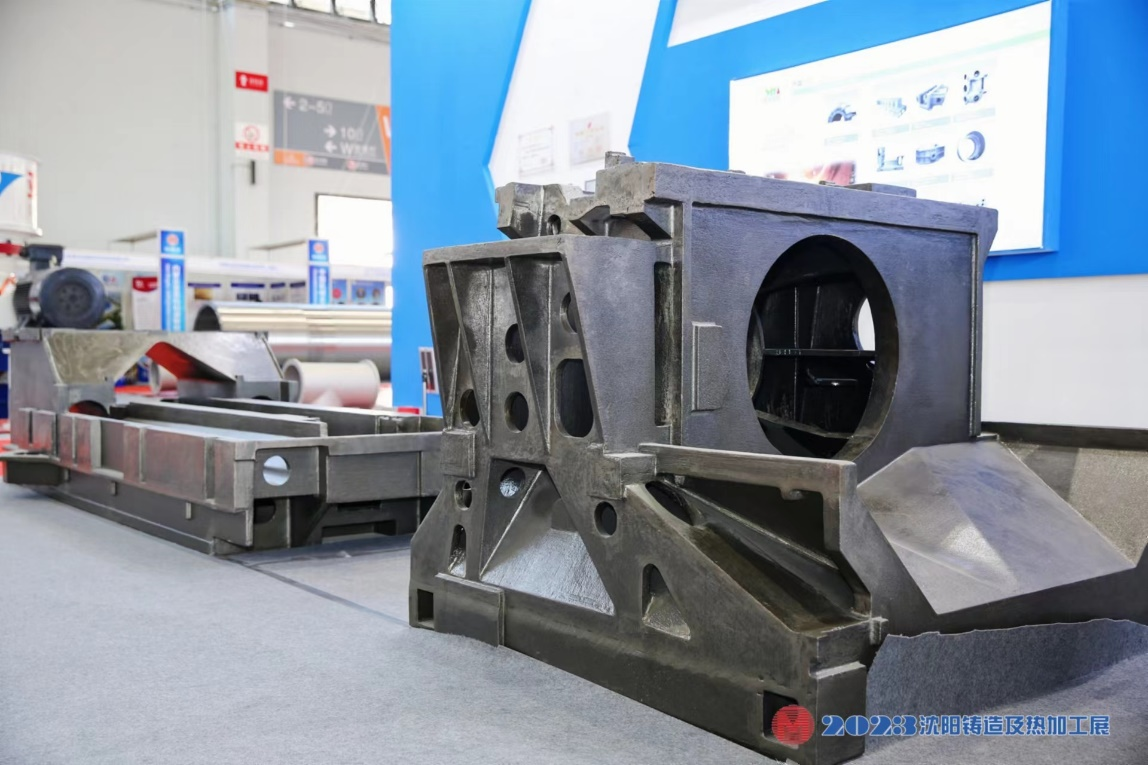

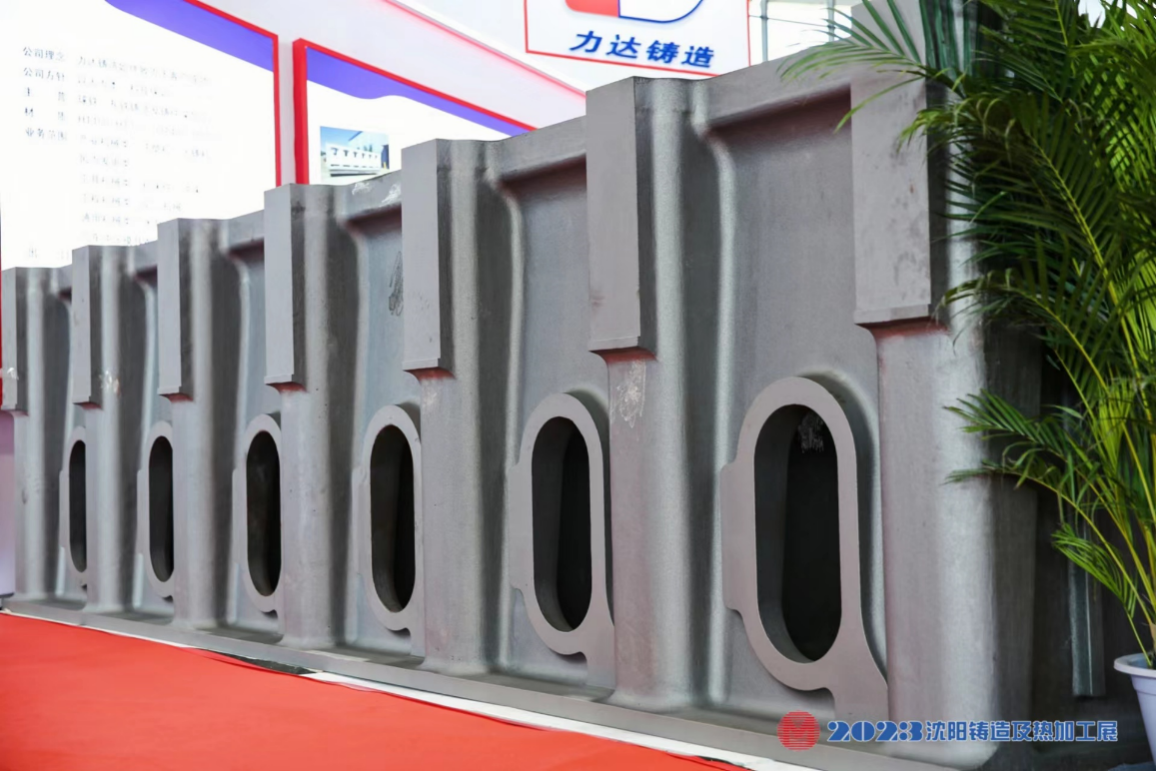

A 27t bedplate casting presented by Fuxin Lida, measuring 9600mmx2200mmx1000mm, emerged as a centerpiece due to its exceptional strength, rigidity, precision, and superior machinability. Fu’an Heavy Industry showcased a 6.6t bogie casting characterized by a highly complex geometry and a minimum wall thickness of just 17mm, serving as a "living testament" to the company’s advanced foundry capabilities. Yunhe Machinery exhibited two critical component-a 2.4t rear support and a 1.4t wheel hub-both fabricated from high-performance alloy steel with tensile strength exceeding 620 MPa, demonstrating outstanding resilience under extreme operational conditions. Shenyang Yinfeng displayed a 4.1t slide rest casting, a core element of high-precision machine tools, which achieved multiple technological advancements and exemplified industry-leading control over both surface and internal quality. The systematic presentation of high-precision and innovative castings enabled attendees to gain direct insight into the diversified advancement of the foundry sector across key industries such as automotive, rail transit, and machine tools, leaving a powerful impression through both technical substance and physical presence. Visitors engaged in close inspection and active discussion, fostering a dynamic and interactive atmosphere throughout the exhibition venue.

Here, suppliers and buyers converge, engage, and collaborate--ranging from candid discussions on pressing demand-side challenges to in-depth exchanges of industry expertise, and from aligning on cooperative frameworks to formalizing mutually beneficial agreements. Each interaction serves to energize the industrial ecosystem. The 2025 Northeast Asia Foundry Industry Chain Collaborative Development Forum, the High-Quality Development Conference of the Silica Sand Industry, the Innovation and Technology Seminar on Rail Transit Foundry, the Development Forum on Precision Foundry Transformation and Upgrading, and the Special Seminar on Material Innovation and Process Optimization in Machine Tool Castings--along with a series of related events--are closely integrated with specialized exhibition zones, bringing together leading experts and fostering intellectual exchange through forward-looking insights to collectively explore pathways for high-quality industrial advancement.

Currently, the momentum of coordinated development in Northeast Asia is gaining strength. How can technology be leveraged to enhance efficiency and strengthen the quality-driven core competitiveness of the foundry industry, particularly in the production of core components for large-scale equipment and high-complexity castings? Furthermore, how can a collaborative industrial ecosystem be established to harness regional synergies, ascend the global value chain, and achieve a strategic transformation-from exporting low-end casting capacity to delivering high-end casting brands and advanced core technologies? These critical questions, central to the future of the industry, are not only posed but also addressed within this context.

With a more open mindset and resolute determination, China Foundry Association will continue to strengthen platform development, consistently stimulate industrial innovation, support the industry in enhancing its global influence and voice, and reinforce the platform's cohesive strength. Together, let us move forward hand in hand, driven by innovation and united through collaboration, ensuring that the momentum generated by this significant event carries forward into every step of our shared future. We would like to extend our sincere gratitude once again to all partners, exhibitors, and professionals in the foundry industry who have participated in and supported this exhibition. It is through your continued trust and support that China Foundry Association’s service platform has been continuously refined and advanced.

High-quality Foundry Development Shines at Metal Shenyang 2023

With the implementation of the strategy of accelerating the construction of a "manufacturing powerhouse" and carrying the expectation of "high-quality development" in the manufacturing industry, 2023 China (Shenyang) International Foundry and Thermal Processing Exhibition (Metal Shenyang) kicked off jointly with the 21st China International Equipment Manufacturing Expo on September 1.

The total exhibition area is 110000 square meters, with 11 exhibition areas and over 1000 exhibitors. As an important part of the Manufacturing Expo, the Metal Shenyang 2023 focuses on the latest casting technology and application, and nearly 200 exhibitors bring their flagship products, equipment and solutions to the exhibition.

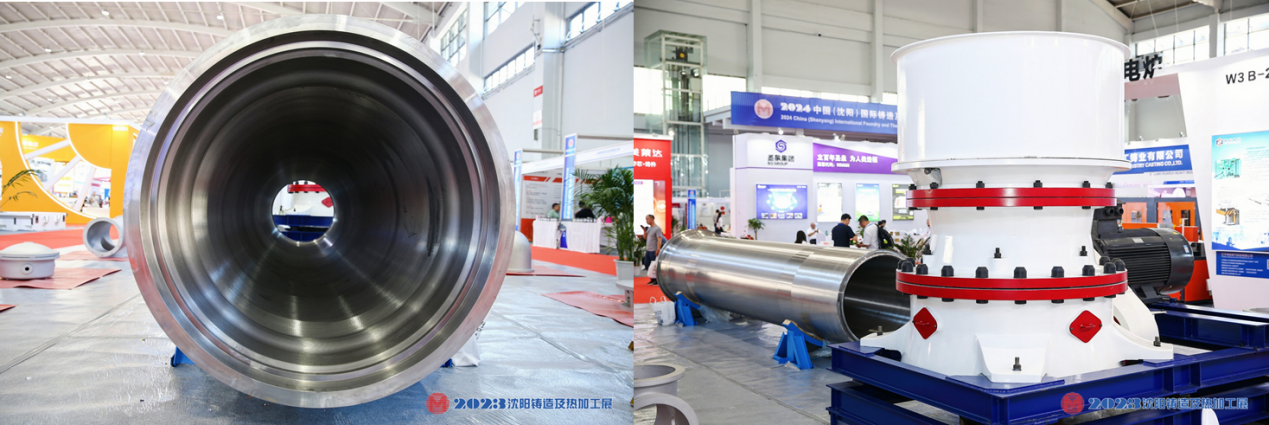

Dalian Huarui’s 55t wind power casting (bearing seat)

High Quality Machine Tool Casting of Shenyang Machine Tool Yinfeng Foundry, GENERTEC

The 45t marine diesel engine cylinder casting produced by LK Group’s Fuxin Lida Company

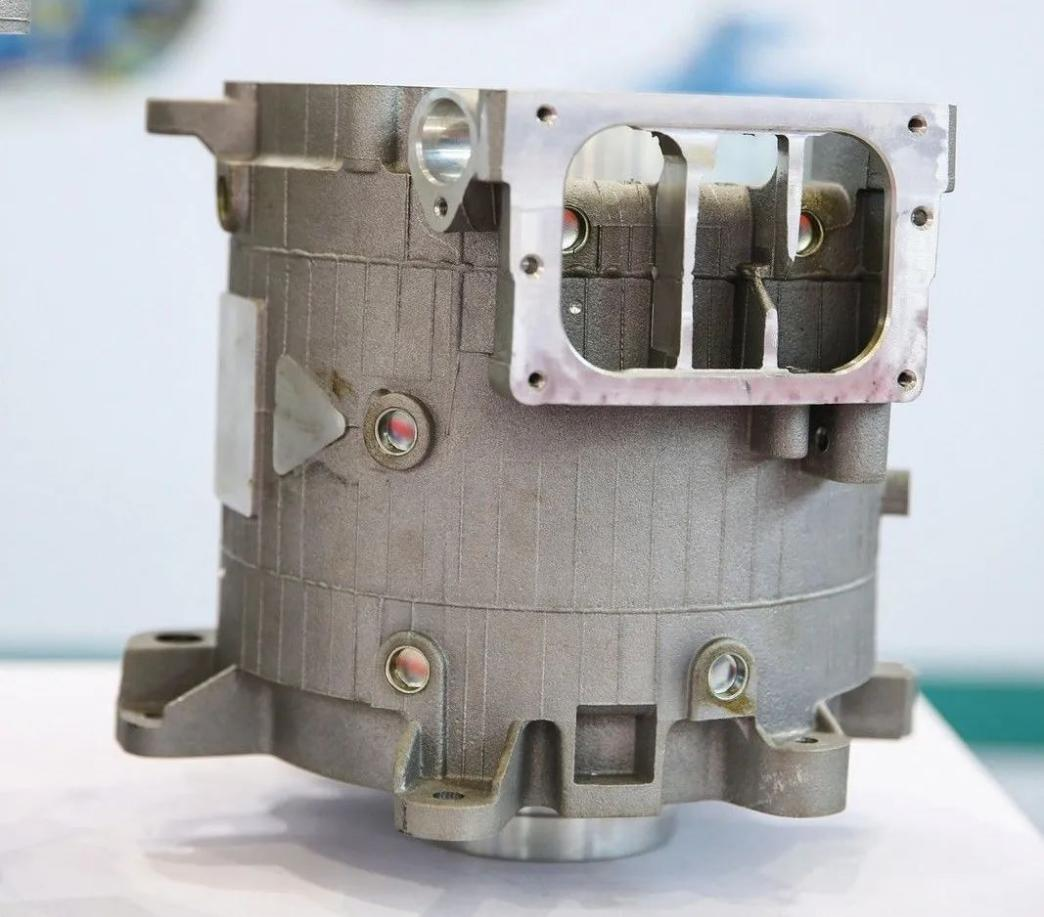

Liquid cooled shell for hybrid electric vehicles cast by Shenyue Foundry

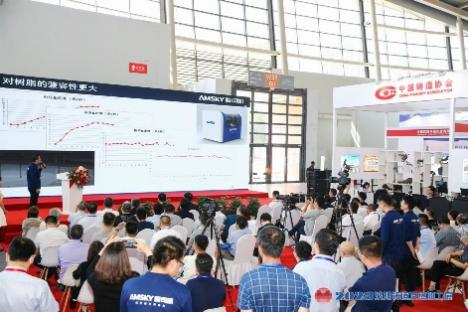

Amsky’s Sand 3D Printer - Storm S1800

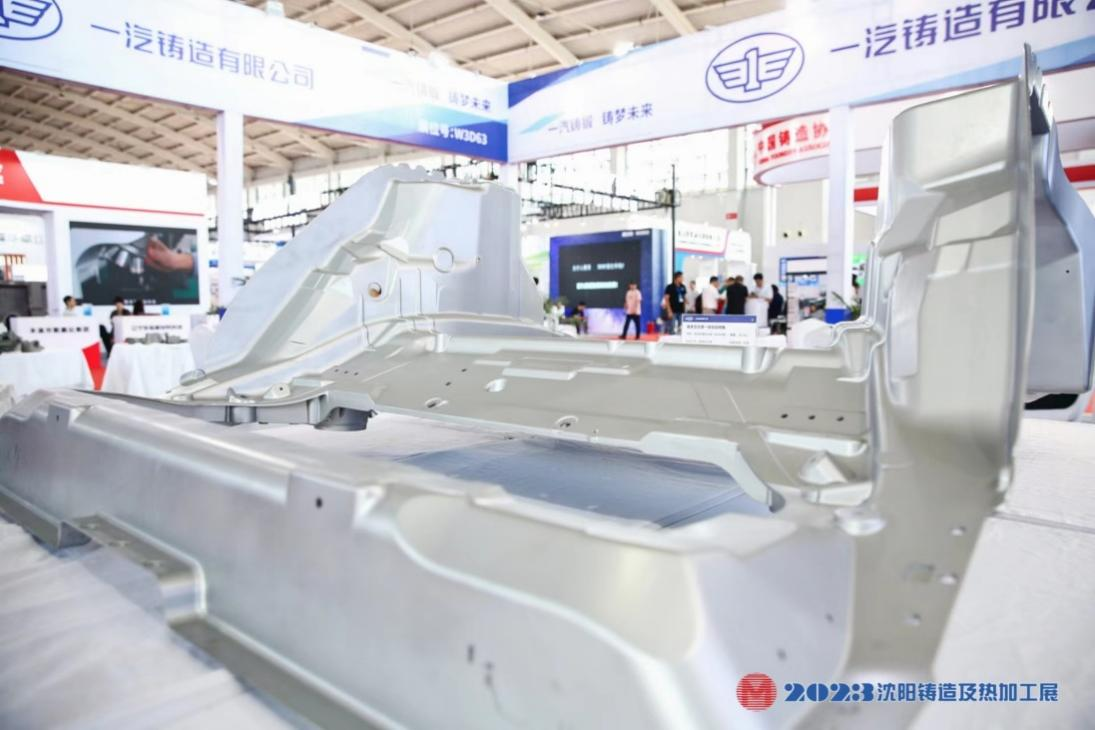

The core solution to auto lightweight from FAW Foundry

The exhibitor lineup covered the entire casting industry chain and built an one-stop platform. Nearly 200 leading enterprises in the foundry and related industry have displayed their new products and technologies, including Inner Mongolia First Machinery Group, a leading enterprise in military equipment, Shenyang Yate, a global leader in centrifugal casting and centrifugal equipment, as well as KOCEL Group, Benxi Shentie, Shengquan Group, Tianjin Yuye Silicon Carbide, Yonghong Group, Dalian Yuyang, Lianxin Casting Sand Group, Shengquan Keliyuan, Tianyang New Materials, Dongyi Spectrometer, Qingdao Tede, ASIMCO, GF, FOSECO, Chongqing Changjiang Materials, Longsheng Foundry, etc..

A number of professional areas were highlighted at the exhibition, including high-end castings exhibition area, raw and auxiliary materials, equipment, molds, intelligent manufacturing, 3D printing, art castings, calligraphy and painting exhibition area, as well as industry clusters, showcasing unique features and achievements,for further market expansion and cooperation.

Dozens of concurrent events, such as summit meetings, forums, technical seminars, new product launch, international exchanges, and awards were held, connecting upstream and downstream supply and demand chain, indicating the direction to move towards a new future of high-quality development of the foundry industry.

Foundry Summits Meet with the Old Industrial Base

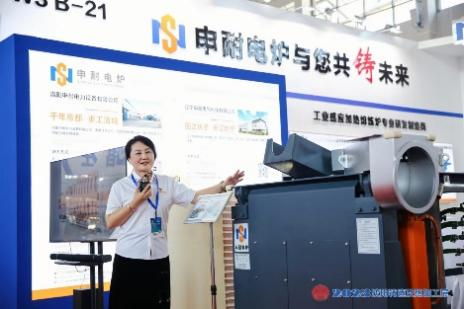

Foundry Industry Development Summit and 2023 China Automotive Casting Lightweight Forum: The forum invited senior specialists, academic experts, and industry elites from the casting industry, upstream and downstream industries, especially the automotive industry, to gather in Shenyang. It focuses on the hot spots in the new development stage of the automotive industry, new energy and lightweight technologies that have brought significant impacts on the automotive casting industry, and sharing the latest automotive casting technology, planning for medium and long-term development, and discussing about the future development of automobile castings.

Lu Baosheng, Senior Director of the Product Technology Department of FAW Foundry, made a report on the development of thin-walled cylinder block castings. He introduced the process of producing thin-walled cylinder blocks (wall thickness 2.8mm) using 3D printed sand cores and core assembly molding technology, and explored the impact of key technical parameters on quality. The 3D printing sand core process has great flexibility and high dimensional accuracy, and will be increasingly applied in product development and mass production.

Liu Yue, Executive Vice President and Secretary General of Liaoning Casting and Forging Industry Association, and Professor of Northeastern University, presented a report on the "Current Situation and Future Development of Foundry Industry in Northeast China". The report summarizes the development process, casting characteristics, advantages of raw and auxiliary materials, and current situation of talent cultivation for the industry.

Kan Xingyu, Executive Director of Liaoning Huade Technology Co., Ltd., presented a report on "Quality Management of Components in German Automotive Supply Chain - Main Engine Factory". With the rapid development of China's automotive industry, especially the new energy vehicle industry, the quality management system of component suppliers in the automotive supply chain also needs to be rapidly improved. Mr. Kan explained the main functions and contents of QMT for quality management of automotive parts in Germany in the report.

Dr. Konrad Wei ß from Aachen University of Technology, explains the "Lightweight Solutions for Automotive Castings" in his report. The report mainly elaborates on the connection and development of design, research and development, and manufacturing, through specific cases.

Xu Zhengshun, General Manager of Shenzhen Zhichuang International Exhibition Co., Ltd. and former General Manager of Siemens CNC China Business, brought a report titled "Digital Twin Technology Leading the Development and Enlightenment of Metal Cutting Machine Tools". The report analyzes the application of digital twin technology in the design, production, and use of advanced CNC machine tools, and discusses about the future development characteristics and inspiration of intelligent manufacturing of machine tools.

Xue Yueteng, Manager of Non-ferrous Products, Vesuvius Foundry Technology (Jiangsu) Co., Ltd., presented a report on “Achieving grain refinement and improving the performance of aluminum alloy castings through new fluxes”.

Zhao Yang, Application Manager of Magma (Suzhou) presented a report on "Mold Temperature Analysis of Large Integrated Die Castings Based on MAGMASOFT Simulation Analysis".

Gao Guoping, General Manager of Shenyang Hongyu Technology Co., Ltd. and Distinguished Professor of Northeastern University, shared the report on "Practice of Digital Transformation and Industrial Internet Empowering the Transformation of Casting and Die Casting Enterprises".

Li Wenjun, Chairman of Dalian Yuyang Industrial Intelligence Co., Ltd., made a report on "Automatic Plan of Flexible Cleaning and Polishing for the Mixed Line Production of Automotive Castings”.

Cao Changmao, Secretary of the Board of Directors, Fujian Shenyue Casting Co., Ltd., delivered a report on the "Electric Drive Integrated Casting and Lost Foam Mold Solution".

The 2023 Metal Shenyang exhibition once again proves the vitality of the old industrial base, the innovation of enterprises, and the cohesion of the exhibition platform. Thank you again to all partners, exhibitors, and foundry industry colleagues who have attended the exhibition. Let’s cast a brilliant future together. Looking forward to meeting you again in September 2024, Shenyang!