As the "crowning jewels" of Metal China and Diecasting China, the casting exhibits of each session not only showcase the innovative height and industrial depth of foundry technology but also testify to the transformation of China's foundry industry from "manufacturing" to "intelligent manufacturing", highlighting the solid progress of industrial upgrading and the construction of a manufacturing powerhouse.

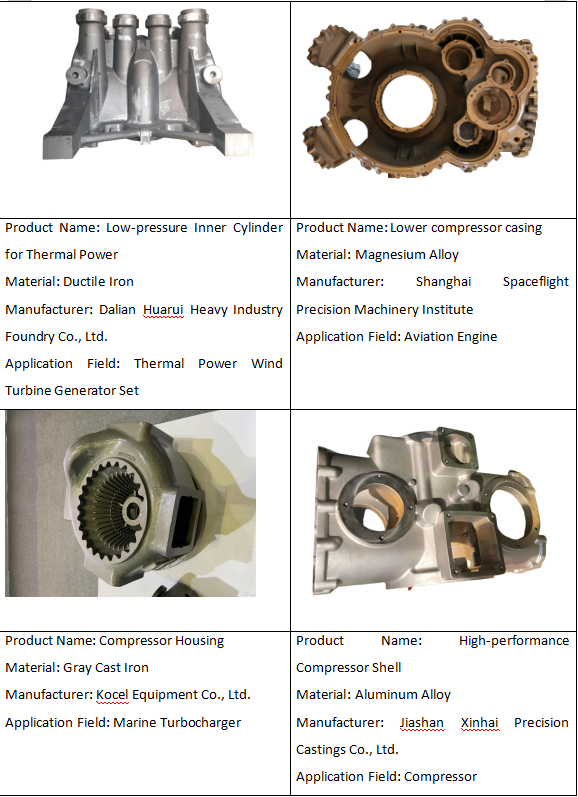

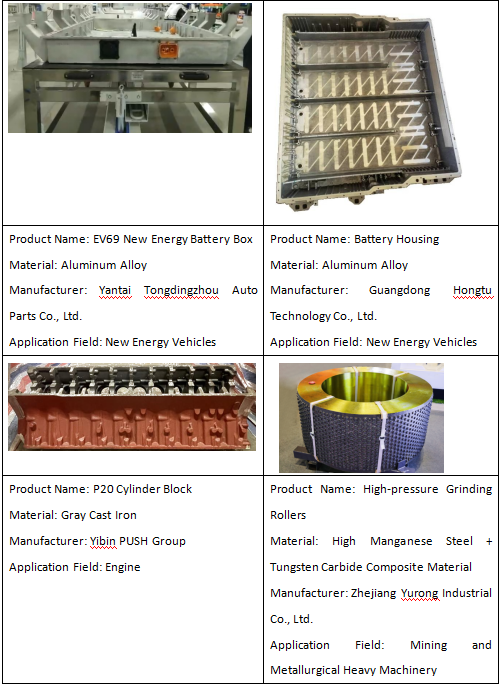

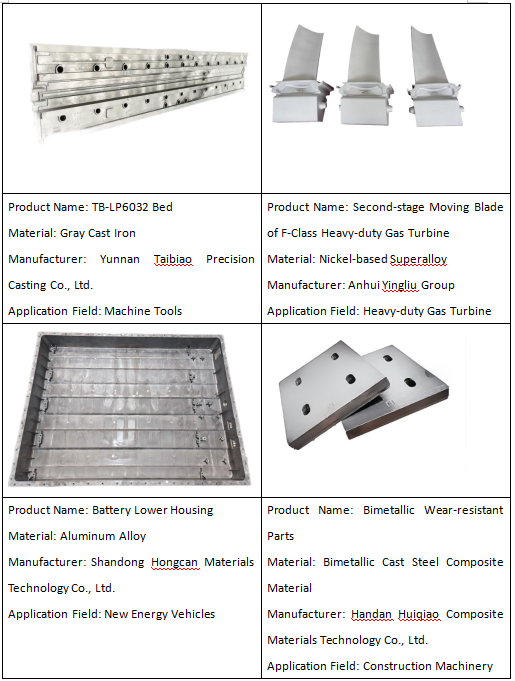

Castings of the Year (2021-2025)

2021

2022

2023

2024

2025

From high-quality casting exhibits, see the industry development trend

1. Lightweighting: In accordance with the carbon strategy, through material substitution (e.g., aluminum alloy, magnesium alloy and composite materials) and structural optimization design, the weight of castings is reduced, and simultaneously, the energy efficiency and operational performance of equipment are significantly enhanced.

2. Mega-casting: By utilizing large-scale integrated forming technology, multiple parts are integrated into a single complex component, which reduces assembly and improves the overall structural strength and production efficiency.

3. Intelligence: By integrating advanced techniques such as 3D printing, multi-process manufacturing, digital twins, and intelligent inspection, precise control of the casting process is achieved, thereby significantly increasing product qualification rate and production flexibility.

4. High-end: Shifting from traditional supporting roles to core components of high-end equipment, breakthroughs in the production of key castings have been made in fields such as aerospace, gas turbines and new energy.

5. Composite: New types of castings, such as bimetallic and composite materials, are developed to meet multiple performance requirements and expand the application scope of castings under extreme working conditions.

6. Extreme Working Conditions: For high-temperature, high-pressure, and highly corrosive environments, special material castings, such as high-temperature alloys and titanium alloys, are developed to meet the high-end requirements of aircraft engines, gas turbines, and special equipment.

Prospects and Focus

The high-quality castings on display at Metal China/Diecasting China are not only industry benchmarks but also vivid illustrations of the transition from "Made in China" to "Created in China". Looking forward to the "15th Five-Year Plan", China's foundry industry will fully commence a new journey of high-quality development.

As the "Barometer" and "Wind vane" of the foundry industry in China, with 120,000sqm exhibition area and over 1,200 industry leading companies, Metal China 2026/Diecasting China 2026 and Nonferrous China 2026 are positioned to provide a strategic platform for global industry players to exchange ideas, connect resources and create value. We sincerely invite the global industry to join this grand event, witness the trends, and jointly draw a new blueprint for the high-quality development of the industry!

We are looking forward to your participation at the National Exhibition and Convention Center (Shanghai) from May 6th to 9th, 2026.

Pre-registration benefits:

*VIP Pass

*Exhibition catalogue

*Business matching

*Coffee voucher

For visit or exhibit, please contact:

Maggie Li

limengmeng@foundry.com.cn