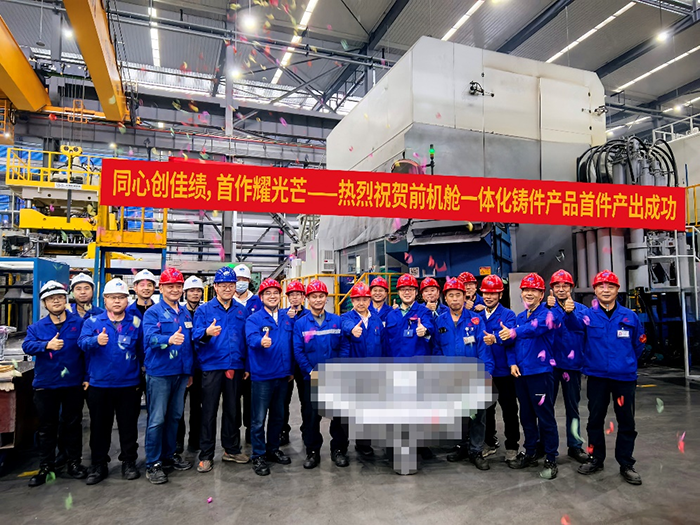

On November 1, 2025, Yujiang Die Casting successfully completed the trial production of a large-scale integrated front engine structural component at the die-casting production line of its third manufacturing facility. As the heaviest single diecasting undertaken by the company to date, it imposes stringent requirements on process control precision, equipment stability, and system coordination. The successful production of the first unit represents a significant milestone in the company's advancement in giga-diecasting technology and further strengthens its comprehensive capabilities in manufacturing high-end automotive structural components.

This front engine structural component serves as a critical load-bearing element within the vehicle's overall architecture. It employs the widely adopted integrated die-casting manufacturing process, which replaces the conventional multi-component welding and assembly approach. This design enables structural integration and weight reduction while significantly enhancing the overall rigidity and reliability of the vehicle. The implementation of this process offers substantial benefits in terms of improved production efficiency, reduced assembly costs, and consistent quality control. The component's performance aligns with current industry-leading standards, providing robust support for the structural optimization of new energy vehicles.

During the trial production phase, the team successfully resolved critical technical challenges, including filling integrity, internal defect control, and dimensional deformation management through iterative process validation and systematic parameter optimization, ensuring first-time compliance with quality standards. This achievement reflects the strong execution and operational excellence of the Yujiang team, driven by a collaborative, cross-functional effort and a commitment to overcoming complex engineering obstacles.

The successful trial run is built upon the company's long-term technological expertise in die-casting. Equipped with a 4400T giga intelligent die-casting unit, automated production lines, and a comprehensive in-line inspection system, the manufacturing platform ensures stability and reliability in producing high-complexity structural components. Furthermore, close collaboration with engineering teams from leading domestic automotive component manufacturers has enabled seamless coordination from product design to process implementation, facilitating steady project advancement.

"This achievement reflects the team's professional collaboration and deep technological accumulation," stated the General Manager of Yujiang Die Casting, "We will leverage this success as an opportunity to continuously refine our process systems, enhance intelligent manufacturing and lean production capabilities, and remain committed to delivering higher-quality, more competitive products and services to our customers."

Currently, the company is systematically advancing process verification and mass production preparations, with a strong focus on ensuring timely and high-quality product delivery. This technological advancement also offers a valuable reference and exploratory pathway for the automotive industry in promoting the integration and lightweighting of structural components.

Yujiang die-casting, focusing on the process development, manufacturing and sales of precision aluminum alloy auto parts, is a high-tech enterprise integrating mold design, research and development, manufacturing to die-casting, machine addition, testing and assembly.